Definition: to connect or joint rail tracks

A rail fishplate, also called splice bar or joint bar, is a device used to connect the ends of two rails with bolts in a track. It can be divided into 3 types according to light rail, heavy rail and crane rail. The preferred spare part to fix a rail joint bar is fish bolt set, which is always made of a fishtail bolt, rail nut, flat washer and spring washer. Every 2 fishplates (one unit) need 6 or 4 fish bolts.Definition: to connect or joint rail tracks

A rail fishplate, also called splice bar or joint bar, is a device used to connect the ends of two rails with bolts in a track. It can be divided into 3 types according to light rail, heavy rail and crane rail. The preferred spare part to fix a rail joint bar is fish bolt set, which is always made of a fishtail bolt, rail nut, flat washer and spring washer. Every 2 fishplates (one unit) need 6 or 4 fish bolts.

Function: to maintain the extended rail track’s continuity

There are bolt holes in the middle of a fishplate used in railway track. Above and below the hole horizontal axis, there are up and down working faces to touch the bottom of railhead and the top of rail flange, respectively. The backside of above mentioned up-working-face forms a transition section over the rail surface while extending upward, which becomes a bridge-arc of high in the middle but low at two ends, orientating along the length of the rail joint bars. Such bridge-arc frame is simple, capable of reducing the impact of carriage wheels to steel rail joints and strengthening the continuity of longitudinal strain at the steel rail joints in order to improve the train’s smooth passing.

Types of railway fish plates

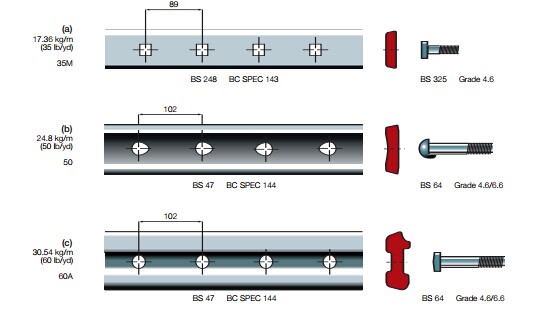

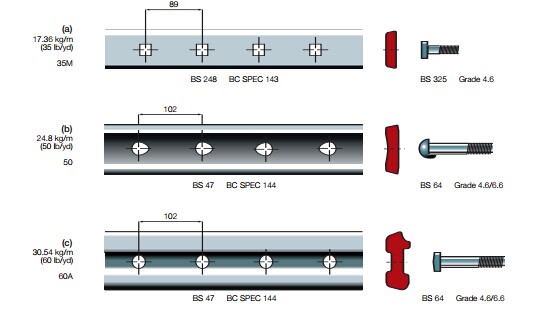

According to textures, railway track fishplates can be made of nodular cast iron, Q235 rolling and forging/blacksmithing. Models of the fishplates joint can be divided depending on rail weight such as 8kg, 12kg, 15kg, 18kg, 22kg, 24kg, 30kg, 38kg, 43kg, 50kg, 60kg,75kg, etc.

Among them:

- Light rail includes 8kg, 12kg, 15kg, 18kg, 22kg, 24kg and 30kg;

- Heavy rail includes 38kg, 43kg, 50kg and 60kg;

- Crane rail includes QU70, QU80, QU100, QU120, etc.

- There are also various international standards of fishplates such as BS47 and UIC series, e.g. BS80A, BS75R, UIC60, UIC54, etc.

Surface requests of railroad fishplates

The fishplate is a connecting link between the preceding and the following steel rails. Therefore, if the quality of the fishplate is poor, the caused consequences would be unimaginable. Many quality inspection rules shall be followed during production, including surface requests as below:

The fishplate surface should be clean and smooth without any crack, scarring, scratches or any other defects. The end faces shall not be with any shrinkage cavity mark or intercalation. The allowed surface defects and relative geometrical quantity for both light and heavy rails shall be within the range of standard provisions.

A fishplate of rail track after rolling should be straight without significant bending or torsion.

Assembling and maintenance of fish plates in railway

To ensure the fine use of railway accessories and fittings including rail splice bars, it is necessary to maintain the fishplates from time to time, to improve the equipment quality and avoid any accidents. Assembling and maintenance standards of railway fish plates are as below:

The fishplates’ assembling device in place without any wounds or cracks; fish bolts well fixed.

Each connected rod or out-lock device is not found with any wounds or cracks. No grinding or corrosion on the rod body and abrasion pin hole less than 1mm with good insulation.

All iron rods’ insulation connection and the insulation link between out-lock iron and gauge rod are both fine. At uninsulated condition, 3mm gap shall be kept and not into other parts. Bolts are fixed well in place as well.

To guarantee none crack is found on the shell of the switch machine to install fishplates, and the installation is firm under good lock condition.

To ensure the oil tank circuit in good protected condition without any damage or being buried by ballasts or other debris.