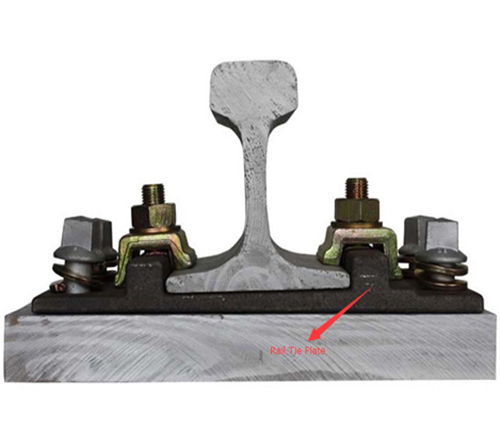

Rail Tie Plate

Rail iron tie plate (also called sole plate, base plate) and elastic cushion are installed between the rails and the sleepers to disperse the longitudinal forces to the sleepers pushed by the rail and freight. Rail plates with shoulders can also bear the lateral force.

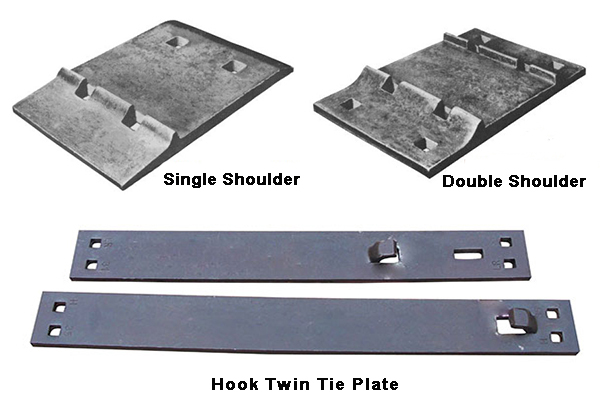

Rail tie plate helps to fix the rail and fastening system, protect the ties against being cut and keep the rail gauge in the right place. It is usually installed with rail bolts or spikes. There are single shoulder rail tie plate, double shoulder rail tie plate and hook twin tie plate according to different rail weights.

| Rail tie plate | Applicable condition | Processing way | Material |

| Singer shoulder tie plate |

Rail weight 56lb~100lb |

casting, forging, rolling |

QT500-7 or QT450-10 (low carbon steel or high carbon steel by forging, and low carbon steel S275JR, Q235,etc. by rolling.) |

| Double shoulder tie plate |

Rail weight ≥100lb |

||

| Hook twin tie plate | turnout |

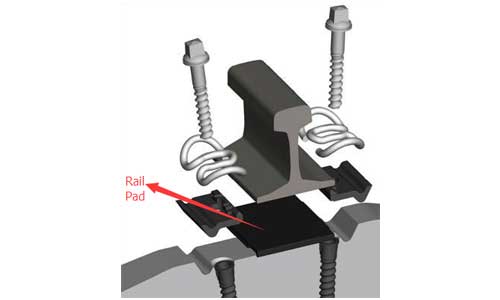

Rail Rubber Pad

Railway rubber pad, also called elastic cushion, is used on concrete sleepers rather than on timber. It is used to reduce the fatigue cracking of the concrete ties. It can buffer the impact loads and insulate the rails from sleepers. Rail rubber pad, plastic sleeper bearing plate, cork rubber pad and wooden plate are common cushions, while rail rubber pad is superior in general performance. AGICO can supply rubber pads made from natural rubber, SBR, chloroprene rubber, HDPE and EVA.

Characteristics of rail rubber pad

- Shock absorbing, wearing resisting, steady

- Flexible, not easily deformed or broken under various temperature

- Good aging resistance

- Easy installation, long service life, low maintenance and replacement cost

- Silent running

With the above characteristics, the use of rail rubber pads can reduce the maintenance requirement and chances of traffic accidents thus increase the transportation capability.

Qualified rail rubber pads should have smooth surface and trim. Unsmoothed surface may weaken the properties of the pads. Rail pads we manufactured have passed strict tests on stiffness, tensile strength, elongation, aging, insulation and static rigidity etc.

Generally, we use rubber rail pad instead of rail plate on concrete sleepers because rubber rail pad have great compressive strength.

AGICO can supply rail pads of different sizes according to the dimensions of the load and rail base. As a leading railway material supplier, AGICO pays great efforts to the quality of products. The inspection report of products is necessary, and we have an overall test on the products before putting them into the market. The QC test is selected at random in the products. Our QC tests check the products randomly and the unqualified ones will be rejected. While the inspection will examine every single piece of the products. Besides the strict ISO9001-2008 quality control system and internal management, we have equipped with full range of inspection tools to ensure every piece of our products meets the requirements of the customers.