Stainless steel bolts and nuts are essential components in the manufacturing and construction industries. They are known for their resistance to rust and corrosion, making them a popular choice for various applications. In this guide, we will discuss everything you need to know about stainless steel bolts and nuts, from their definition to their types, advantages, and disadvantages.

1.What is a Stainless Steel Bolt?

A stainless steel bolt is a fastener made from stainless steel materials that provide superior resistance to rust and corrosion. Stainless steel bolts come in various shapes, sizes, and designs to meet specific application requirements. They are widely used in industries such as construction, automotive, aerospace, marine, and others, due to their strength and durability.

Stainless steel bolts and nuts are designed to hold together two or more components. They typically come with a threaded shaft and a head, which can be hexagonal, square, or circular, among others. The shaft of a bolt is inserted into a hole, and the nut is threaded onto the other end to secure the components in place.2. Material Introduction of Stainless Steel Bolts and Nuts

Stainless steel bolts and nuts come in a variety of materials and types, making it important to understand their classification. Among the different materials, 304, 305, and 316 stainless steel are commonly used in the industry.

304 stainless steel bolts and nuts are one of the most commonly used materials for fasteners due to their excellent corrosion resistance, durability, and strength. They contain 18% chromium and 8% nickel, and their properties make them suitable for use in a wide range of applications, including food processing, medical equipment, and marine environments.

305 stainless steel bolts and nuts are similar to 304 stainless steel, but with a slightly lower nickel content, making them more affordable. They are typically used in applications that do not require the same level of corrosion resistance as 304 stainless steel, such as in the automotive and construction industries.

316 stainless steel bolts and nuts are a premium material due to their high corrosion resistance, making them an ideal choice for use in harsh environments, such as marine or chemical processing applications. They contain 16% chromium, 10% nickel, and 2% molybdenum, which provide superior resistance to pitting and crevice corrosion.

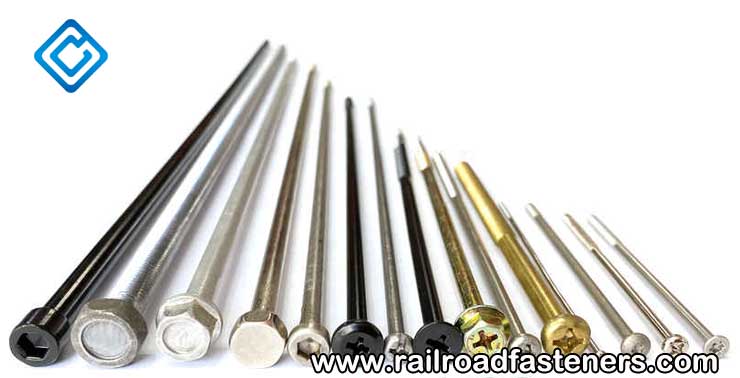

In addition to the differences in materials, stainless steel bolts and nuts also come in a range of different types. Common types include hex bolts, carriage bolts, eye bolts, and lag bolts, each with their own unique characteristics and uses.

Do Stainless Steel Bolts and Nuts Rust?

While stainless steel bolts and nuts are corrosion-resistant, they are not completely immune to rust. Corrosion can occur when the passive layer on the surface of the stainless steel is damaged, exposing the underlying metal to oxygen and moisture.

The degree of corrosion resistance depends on the type of stainless steel and the environment in which it is used. For example, austenitic stainless steel is highly resistant to corrosion in most environments, while martensitic stainless steel is more susceptible to corrosion.What is the Best Quality in Stainless Steel Bolts?

The best quality in stainless steel bolts depends on the application requirements. Austenitic stainless steel is commonly used in applications that require excellent corrosion resistance, such as in the marine and food processing industries. Martensitic stainless steel is used in applications that require high strength and wear resistance, such as in the automotive and aerospace industries. Ferritic stainless steel is used in applications that require resistance to stress corrosion cracking, such as in chemical processing plants.

3. Classification of Stainless Steel Bolts and Nuts

Stainless steel bolts and nuts are classified based on their materials, types, and specific uses. Among the different types, hex bolts, carriage bolts, eye bolts, and lag bolts are commonly used in various applications.

- Hex bolts are named for their hexagonal heads and are used in a variety of construction and machinery applications. They come in a range of sizes and materials, and their hexagonal shape makes them easy to tighten and loosen with a wrench.

- Carriage bolts have a round head and a square shoulder, making them ideal for use in wood-based applications. The square shoulder helps prevent the bolt from turning as it is tightened, and the round head provides a smooth and finished appearance.

- Eye bolts have a looped head and are used to attach cables or ropes to machinery or other structures. They are commonly used in marine and construction applications, as well as for hanging objects such as lighting fixtures or signs.

- Lag bolts are similar to hex bolts, but with a pointed tip and a coarse thread. They are typically used to secure heavy objects to wood or other materials, such as attaching a fence post to a concrete footing.

4. Introduction to Hot Selling Stainless Steel Bolts

There are many types of stainless steel bolts available in the market, but some are more popular than others. Here we will introduce some of the most hot-selling stainless steel bolts.- Hex Head Cap Screws: Hex head cap screws are one of the most commonly used types of stainless steel bolts. They have a six-sided head and are typically used in construction and machinery.

- Socket Head Cap Screws: Socket head cap screws have a cylindrical head and are designed to fit into a socket or hex key. They are commonly used in electronics, automotive and aerospace applications.

- Lag Bolts: Lag bolts have a hexagonal head and are used for securing large items to wood, such as decks or framing. They are commonly made of stainless steel due to their ability to resist corrosion in outdoor environments.

- Carriage Bolts: Carriage bolts have a rounded head and a square shoulder. They are commonly used in furniture assembly, as well as in building and construction applications.

- Machine Screws: Machine screws are used in applications where precision is important. They are commonly used in electronics, medical equipment, and machinery.

- U-bolts: U-bolts are shaped like the letter U and are commonly used to attach pipes and tubes to flat surfaces.

5. What are the disadvantages of stainless steel bolts?

Despite its many advantages, stainless steel bolts do have some disadvantages. One of the main disadvantages is the cost. Stainless steel bolts are typically more expensive than other types of bolts, such as carbon steel or zinc-plated bolts. Additionally, stainless steel bolts may not be suitable for certain applications that require very high tensile strength, as they are not as strong as some other types of bolts. Finally, stainless steel bolts can be difficult to machine, which can make them difficult to work with in certain applications.

6. Stainless steel bolts and steel bolts

When it comes to strength, steel bolts are generally stronger than stainless steel bolts. However, stainless steel bolts are more corrosion-resistant, making them ideal for use in environments where corrosion is a concern. Stainless steel bolts are also more aesthetically pleasing, as they have a bright, shiny finish that looks great in many applications.

When deciding between stainless steel bolts and steel bolts, it is important to consider the environment in which they will be used. If corrosion is a concern, stainless steel bolts are usually the best choice. If strength is the primary concern, steel bolts may be the better choice. It is also important to consider the cost of the bolts, as stainless steel bolts are typically more expensive than steel bolts.When using stainless steel bolts, it is important to avoid using them in certain environments. For example, stainless steel bolts should not be used in saltwater environments, as the salt can cause them to corrode quickly. Additionally, stainless steel bolts should not be used with other types of metal that are not compatible, as this can cause galvanic corrosion.

In terms of maintenance, stainless steel bolts are relatively low-maintenance. They do not require any special coatings or treatments to maintain their corrosion resistance, although they may need to be cleaned periodically to maintain their appearance.

Conclusion

Stainless steel bolts are an excellent choice for many applications due to their corrosion resistance and durability. With so many different types of stainless steel bolts available, it is important to choose the right type for your specific application. By understanding the different materials and types of stainless steel bolts available, you can make an informed decision and choose the best bolt for your needs. Whether you are working on a construction project or assembling furniture, stainless steel bolts can provide the strength and corrosion resistance you need for a successful project.